We are starting a series of posts called, Meet Your Makers. A little project here at bambu that provides a glimpse, in and around, and behind the products that we make, the people we work with, and the process we take in making our bamboo cutting boards, bamboo plates and bamboo utensils.

Our model is unique. We live and work "at the source" of our production. What we sometimes take for granted, is in fact, a special component of our brand. We have the ability to share the work we do, and the people we work with in developing and producing our products. Here in China we source ourselves the renewable materials we use. Eco friendly materials like bamboo, cork, and hemp.

We are also onsite daily in the workshops and small factories where we produce our products. We have a small, dedicated and experienced team responsible for our product development, production, and quality management.

We never tire of the countryside and walking among the stands of bamboo. Bamboo grows best on hillsides. Local farmers lease areas of land from which they harvest the bamboo culms. (A culm is the term used for a bamboo tree, or stalk).

In the making of our products, there are many steps and numerous hands. In this first post, you will see the second stage of splitting the bamboo.

We are the first company to introduce bamboo to the housewares industry. In our 22 years, we have developed a depth of knowledge about the material and about the production process.

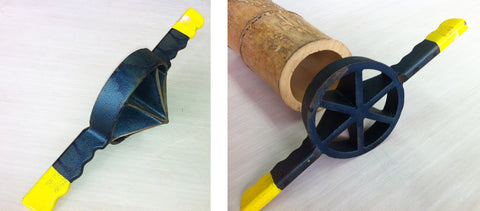

The two video clips below show one of the first stages of production - bamboo splitting. You'll see that splitting the bamboo culm is still a fairly rudimentary process. The process has been mechanized from the original handle-held tools. (See below for an example of a bamboo culm splitter.)

This second clip shows the same process, but from a different angle. You can see that there is a double-cutting action on the same machine which doubles the output.

And in contrast, below is the tool that was used to cut a bamboo culm before it was mechanized. This vintage hand tool would essentially do the same thing, but with a lot more work and a lot less output. These are no longer used in bamboo production today. It's not hard to imagine why!

Bamboo provides a livelihood for thousands of people in China. It is a source of income, a source of beauty, and a source of daily use and enjoyment in cooking and eating, food preparation, tea drinking, and transportation. Bamboo has enormous historical significance in China. Here's one interesting example:

The first multiplication table was created over 2000 years ago... on bamboo strips! The article can be found here.

We'll be sharing more in upcoming Meet Your Makers series.